Joan Weir: The Only Girl in the Welding Shop

"I was there..."

by Molly Martin, 2019, originally published on tradeswomn blog

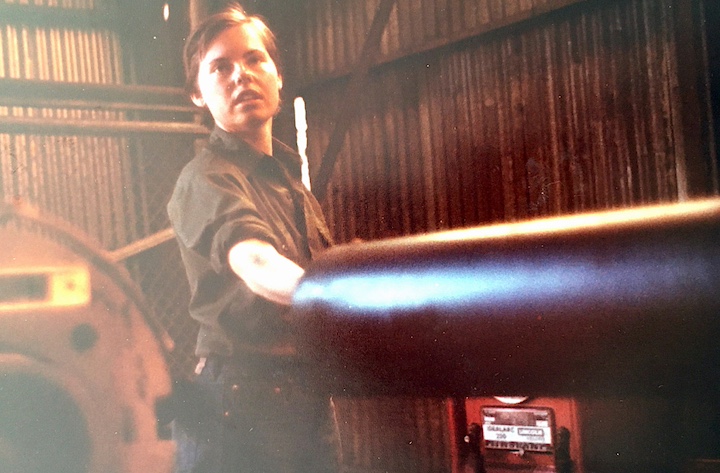

Joan welding light poles for the Bay Bridge, 1976.

| This article is the second of a series of three pieces in which longtime tradeswoman activist Molly Martin profiles female friends in the trades: Carla Jean Johnson, a carpenter and disability activist; Joan Weir, a welder who fought through unsafe working conditions and discrimination; and Susie Suafai, who helped bring women into the trades through apprenticeship systems. |

In 1972, a junior in high school, Joan Weir had already taken all the drafting classes her Los Angeles school offered. She’d been working with her father building a car so she took her father’s advice and enrolled in the welding class. The teacher said if she could fire up a torch she could stay in the class. It was a test no one else had to take. She was the only girl.

Joan took the class and got hooked on welding. The first year she excelled so much she was teaching the other students how to weld. By her senior year she was shirking all her other classes, spending days in the machine shop building projects. That year she won a national award from the Lincoln Arc Welding Foundation for TIG welding brass but she didn’t graduate high school. Joan Weir was a welding phenom.

That summer she got her first job. It was piecework building motorcycle accessories. She said:

They needed someone who could TIG (tungsten inert gas) weld. That was new technology back then. It’s an electric spark that comes out of a piece of tungsten, where you can weld ferrous and non-ferrous materials and it’s like a fine art because it’s a smaller weld you’re making.

Again she was the only female on the job:

I was welding in a metal building where it was well over 90 degrees. I remember lifting my welding hood to find that my sleeve was on fire. I looked down the line and all the guys were just watching. They weren’t helping me. They just wanted to see me take my shirt off. Of course I had a T-shirt on underneath so it was so ridiculous.

I first met Joan Weir in the late 1970s. With our mutual friend, Cheryl Parker, we bonded as some of the few early tradeswomen in the San Francisco Bay Area. Cheryl and I got into the electrical trade and Cheryl had attained the rank of Chief Building Inspector in the city of Richmond when she died of ovarian cancer in 1992. In 1976 Joan and Cheryl had traveled with a convoy of tradeswomen and their supporters to Los Angeles to petition the state government for affirmative action goals and timetables for women in construction apprenticeship.

It was a great moment because we were standing up and talking about what we were experiencing and each one of us had a different story. We got the state of California to enact goals and timetables.

I think of Joan as a Renaissance woman. She has been a general contractor, a carpenter, a plumber, a glass blower, and many other things. But Joan is primarily a welder. She lost her career and nearly her life after being set up to blow up.

In 1980 Joan was working for U.S. Steel in Pittsburg as a maintenance welder. To get the job she took a welding test.

My test was so perfect that they could not refuse to hire me so their recourse was to put me in the ugliest location, which was the cold reduction department, she said.

It was located in a building a mile long. We had four mills that ran consecutively. The steel was brought in in large rolls and was run through each mill to make it thinner. Each roll was a ton maybe two tons at the very end. It was called cold reduction because heat was not being applied. Rollers compressed each sheet as it went through. Water and oil were the lubricants. Next-door was an acid dip where they would roll the big sheets of steel through acid to clean them. As a maintenance welder I led a team of two millwrights and two steamfitters. And jointly we would move on a weekly rotating basis from working days, swing, and graveyard shifts.

We kept the mill running 24/7. These machines were put under a lot of pressure and they would break. The millwrights were in charge of keeping the mill running and the pipefitters would fix any of the piping, which was typically hydraulic whether it was water or air. My job as the welder was to weld any metal part that broke and I also built anything that they would need to install.

It was up to the welder to determine the time length of the repair and if it exceeded three or four hours then they would shut down the mill and all the workers on the mill would be sent home. So it was imperative to not have that happen because the union required that if the worker had already worked four hours then they would get full pay even if sent home. That would cost big bucks. I must admit I always enjoyed saying "Nope send your guys home. It’s gonna take at least five or six hours to repair."

The environment at the plant was extremely unsafe. Cranes carried the large steel rolls over people’s heads. Workers died on a regular basis from the hooks breaking or the roll getting loose. Large forklifts with large extended poles on them carried the rolls along where workers were walking. And because of the extreme noise you could be walking, turn, and not realize that a forklift was right there on top of you. People were hurt on a number of occasions while I worked there.

At U.S. Steel in 1980 it felt like we were working back in the 30s and 40s. Workers were constantly being harassed in many different ways and if you were to go up against management you were likely to end up hurt or killed. That was known. That was just a given.

Teresa (L) and Joan at the Rosie the Riveter contest in Richmond.

The United Steelworkers union covered everybody so if you had a problem with a co-worker the union couldn’t side with one worker or another so it didn’t feel like you had representation–especially as a woman.

I was the only woman welder in the plant, the whole steel industry in Pittsburg. I led a team–two very supportive pipefitters and then two millwrights who were not supportive. This one individual who was a short guy, white, Mormon, had a real issue taking orders from a woman. But I was the team leader and I got paid more.

The atmosphere in the cold reduction department was tense, unsafe, and the work was really demanding. Also the air quality was really bad because we were stuck inside a building that had lots of water and oil mixed into the air we were breathing. We would get inside a mill, literally placing ourselves inside this big machinery, going down into the bowels of it. I never felt very safe going there because I knew this guy didn’t like me. I never expected him to do me physical harm but I worried that he might cause an accident.

A firefighter was required to stand by while I was working, as my clothing would catch fire on a regular basis because of the oil that was constantly coating us. We got used to welding this way. You’d turn, stop welding, ask the fire guy to shoot you with water, he’d douse your clothes and you’d go back to welding again.

One night I was working graveyard so it was a small crew throughout the building. I was welding something up in my weld shop and had to go get some material and I came back to find this guy using my welding hood and welding on my bench. I shouted to him because of the loud machinery and he stopped, he put up the hood, and he back-fisted me. He hit me across my face so hard that I landed against my welding tanks and my hardhat split open.

Two of the other guys on my team came to see what happened. I was injured so the supervisor was called. He sent me home and he let my attacker stay on shift. I was told to come back the following morning for a meeting with the shop steward and the guy who physically attacked me. The shop steward just said that this was something we had to get over.

At that point I contacted an attorney and they told me to take whatever sick time I had and to get off site because it was not safe for me to be there. So I took my week’s leave and then I started calling in and saying that the environment was not safe for me to work in.

Birthday present: Rosie the Riveter hood.

When I showed up for work again it was swing shift on Easter Sunday. There was an emergency. A pipe had bent and needed to be repaired. I had a new pipefitter working with me so we didn’t know each other. First I asked him if he had put the safety blocks in the line because this was a high-pressure hydraulic two-inch line. Then we climbed down the sheet steel that was in the way, down into this pit and I’m up to my knees in oil and hydraulic fluid. The pipe is above the hydraulic fluid. I’ve got my firefighter up above the pit and the pipefitter is down in the pit with me and we get ready to weld it up. I light my big oxy-acetylene rosebud torch to heat the pipe and all of a sudden somebody turns on the line, pressurizes it and there’s an explosion.

My head is literally right over the pipe when it explodes. I don’t realize I’m burnt all over my head with second and third degree burns. I scramble back up the torn up steel next to me to get to my acetylene set up to turn off those valves because I’m afraid of backfire in the lines. I see the pipefitter is burnt so I grab him to get him over to the safety shower and the safety shower doesn’t work. I see a water fountain and I get him to the water fountain and I get his hands into the water and he says "You’ve got to get yourself water," and at that point I start to recognize how burnt I am.

We’re brought into the lunchroom. After 45 minutes or an hour, they finally get us to the hospital, which is unable to provide critical care. So they bring me back to the cold reduction plant. At that point my eyes are shut, I can’t see. My face doesn’t have skin on it.

Nobody responded or cared how badly I was hurt. The head of the department was there and he said that I should go home. They told me only to show up for a safety hearing the following morning. Then the guard, an African American man, looked at me and said, "I will take you home." He risked his job going off shift leaving early to drive me home. When I got home my partner took me to Alta Bates hospital burn unit where they kept me for a week.

After the accident Joan learned glass blowing.

My lawyer and I went to a hearing with the EEOC. My face was still recovering from the burns but the hearing was simply about being hit by a co-worker on the job. It wasn’t about the explosion accident.

She still welds.

EEOC would have found in my favor but the EEOC officer asked me if I was going to take it to federal court and sue U.S. Steel and not knowing any better I said yes. I didn’t understand that it would take five years to even get to court and I was going up against a major corporation. It would cost me and I was unemployed. So they found against me because they said if they’d found for me I couldn’t take it to court. So I lost my suit. And that ended my career in welding.

OSHA never found out about the accident. About a year later I was volunteering for Tradeswomen Inc. with Madeline Mixer at her Women’s Bureau office in the San Francisco Federal Building. Madeline took me down the hall to talk to the head of OSHA who was upset with me that I never contacted them. I didn’t know that I was responsible to contact them. So nothing ever happened to U.S. Steel.

I never learned who turned the pressure back on. We all understood that U.S. Steel was known for killing or maiming workers who complained. And that’s the way the industry ran back in those days.

Joan in her shop at her present job at the vineyard.

For many years after the accident, Joan looked like a reverse raccoon, her face red where the skin had burned off and white around her eyes, which had been protected by plastic safety glasses (they melted). Today, 39 years later, you can’t see the burns unless she points them out. Joan still loves welding and she uses her many skills at her current job working at a vineyard in Sonoma County. In her spare time she teaches beekeeping and building trades to women and girls. She lives in Santa Rosa with her wife Teresa Romaine, a retired painting contractor.

Read more profiles of San Francisco Tradeswomen: